Home : 32mm : Systems :

There have been at least two versions of Blum's Process 32. The '93 Process 32 was Metabox centric and used incremental panel heights and depths. Panel heights were a multiple of 32 with 64mm top/bottom start holes. System rows were 37 from the front, some multiple of 32mm apart and 83mm from the back. Faces were flush to the top and bottom of the panels. Face to box registration was inconsistent because bottom and full height faces were a multiple of 32mm tall and all other faces were a multiple of 32mm - gap. Using all 32m - g faces is the only way this could be a modular system.

There have been at least two versions of Blum's Process 32. The '93 Process 32 was Metabox centric and used incremental panel heights and depths. Panel heights were a multiple of 32 with 64mm top/bottom start holes. System rows were 37 from the front, some multiple of 32mm apart and 83mm from the back. Faces were flush to the top and bottom of the panels. Face to box registration was inconsistent because bottom and full height faces were a multiple of 32mm tall and all other faces were a multiple of 32mm - gap. Using all 32m - g faces is the only way this could be a modular system.

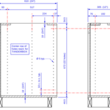

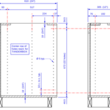

Blum's '04 Process 32 (1.8MB pdf) uses unbalanced panels with 56.5mm top / 46.5 bottom start holes and shifted 32mm increment overlay faces which results in 10/0mm top/bottom reveals (image). Individual and side joined boxes are modular, top joined boxes are not (10mm gap between stacked box faces).

While system rows are a multiple of 32mm apart, box depths are not in 32mm increments. Here, and elsewhere, Blum has opted for American dimensions, e.g. 12 and 24" deep boxes. Only their bottom mount drawer layouts register the drawer faces to boxes consistently, the rest of their layouts shift the bottom drawer slide up 12mm. While Meta and Tandem box drawer sides are in increments of 32mm tall, wood drawers are sized in 2" increments.

32mm system rows and doors (most drawer layouts are not)

See also:

Full Overlay: Other Panel Designs

Drawers: Minus 12

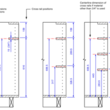

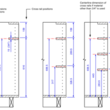

When using a modular 32mm system, all drawers register to all drawer faces consistently. Distances on alignment fixtures or for drilling adjusters/mounting holes are the same for all drawers. Measurement can be off the top or bottom of the box and face. With full overlay cabinets that consistency comes with a cost, it wastes a lot of space. Plus 32 trades some consistency for better usable space. With Plus 32 measurements can only be off the top of the box and face. Plus 32 moves all waste to the bottom of the box.

When using a modular 32mm system, all drawers register to all drawer faces consistently. Distances on alignment fixtures or for drilling adjusters/mounting holes are the same for all drawers. Measurement can be off the top or bottom of the box and face. With full overlay cabinets that consistency comes with a cost, it wastes a lot of space. Plus 32 trades some consistency for better usable space. With Plus 32 measurements can only be off the top of the box and face. Plus 32 moves all waste to the bottom of the box.

In this undermount example, the tradeoff with Process 32 is 20mm less unusable space at the bottom of the cabinet VS inconsistent drawer face registration. Using 32mm increment drawer boxes with Process 32 won't help because the bottom drawer slides are mounted 12mm higher than the rest. Use whatever top reveal you want, the drawings have 49.5mm top starts (3mm reveals, stackable boxes) instead of Process 32's 56.5mm (10mm). The important specifications are the same as the ones in the manual. There's a second drawing showing how to get a 0 bottom reveal with a 48mm start (e.g. for LR32 jig w/ 16mm stops). The only difference is that the faces are shifted down by 1.5mm (different drawer box to face reveals).

See also: Minus 12 and the 3rd 3example in the Full Overlay Undermount topic (maximum space utilization for undermounts that have two rows of mounting holes).

[ link | top ]

In the '04 manual, box dimensions for kitchen cabinets are on page one. They are your typical American 30-1/2" box (wall and base) plus 4" toe and 1-1/2" counter (36" total). Cabinet depths are also sized to American standards, e.g. 24 and 12" deep. Those American dimensions have a cost, especially if you drill system rows with anything less than a double row boring machine. The difference between using the 32mm increments and American dimensions is 17mm, or approximately 5/8".

In the '04 manual, box dimensions for kitchen cabinets are on page one. They are your typical American 30-1/2" box (wall and base) plus 4" toe and 1-1/2" counter (36" total). Cabinet depths are also sized to American standards, e.g. 24 and 12" deep. Those American dimensions have a cost, especially if you drill system rows with anything less than a double row boring machine. The difference between using the 32mm increments and American dimensions is 17mm, or approximately 5/8".

While Blum is heavy on American stantards, I should note that Blum is not alone when it comes to non incremental box depths. This should be discussed in more detail, but the key factor is making the best use of 4x8' sheets. Using applied (instead of dadoed) backs can help when using 32mm increments.

Rail spacing is covered on page two. For some strange reason, only the rails at 606.5mm are centered between system holes. The other rails vary from 1-3mm off center. The 32mm way to handle cross rails is to center them between (or on, whichever is appropriate) system holes, i.e. n x 32mm apart. Because all slides mount to system holes (are the same distance from centered rails), there is no reason not to center the rails. The "Cross rail positions" dimensions are also rather pointless, center to center dimensions is all that matters - it works with 19mm (~3/4") or 16mm (~5/8") stock.

Rail spacing is covered on page two. For some strange reason, only the rails at 606.5mm are centered between system holes. The other rails vary from 1-3mm off center. The 32mm way to handle cross rails is to center them between (or on, whichever is appropriate) system holes, i.e. n x 32mm apart. Because all slides mount to system holes (are the same distance from centered rails), there is no reason not to center the rails. The "Cross rail positions" dimensions are also rather pointless, center to center dimensions is all that matters - it works with 19mm (~3/4") or 16mm (~5/8") stock.

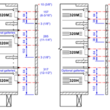

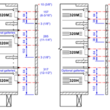

Page five has one of their Metabox layouts. The distances from the top of the drawer face to the first mounting hole are missing. That measurement, for all but the bottom left drawer, is 55mm. Using a 320K instead of the 320M and adding another gallery rail would allow you to drill all the faces 55mm from the top. The same is true for system hole registered faces (Blum uses shifted registration) using a Plus 32 layout. Here both drawers can be 320M's and and the distance from the top of the face is 71mm for all the drawers. Note: 71-55=16mm, the same distance as the system row holes are different (start holes and system VS shifted face registration). While indexing drawer faces from the bottom is common, indexing from the top can provide more options (its the only way Metabox indexing can be consistent). You do have to use the system, Blum's 2" increment wood drawer boxes won't work.

Page five has one of their Metabox layouts. The distances from the top of the drawer face to the first mounting hole are missing. That measurement, for all but the bottom left drawer, is 55mm. Using a 320K instead of the 320M and adding another gallery rail would allow you to drill all the faces 55mm from the top. The same is true for system hole registered faces (Blum uses shifted registration) using a Plus 32 layout. Here both drawers can be 320M's and and the distance from the top of the face is 71mm for all the drawers. Note: 71-55=16mm, the same distance as the system row holes are different (start holes and system VS shifted face registration). While indexing drawer faces from the bottom is common, indexing from the top can provide more options (its the only way Metabox indexing can be consistent). You do have to use the system, Blum's 2" increment wood drawer boxes won't work.

Page six is is the first example of Blum's 2" increment drawers and the first example of inconsistent drawer registration. Here the distance from the top of the drawer face to the drawer box cannot be the same because the drawer boxes (unlike the Metabox slides/sides) are not in 32mm increments. The distance from the bottom of the face to the box is also not consistent because they mount the bottom drawer differently than the rest (bottom mount hole VS top). See also: Process 32 VS Plus 32

Page six is is the first example of Blum's 2" increment drawers and the first example of inconsistent drawer registration. Here the distance from the top of the drawer face to the drawer box cannot be the same because the drawer boxes (unlike the Metabox slides/sides) are not in 32mm increments. The distance from the bottom of the face to the box is also not consistent because they mount the bottom drawer differently than the rest (bottom mount hole VS top). See also: Process 32 VS Plus 32

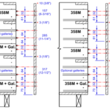

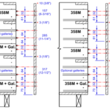

Page nine explains the 12mm difference in registration for the page eight Tandembox layout (image): "The lower holes on 358M TANDEMBOX runners are not accessable. Mounting holes must be manually drilled only for the bottom drawer at 58.5mm". Here you have to drill mounting holes 12mm above the system hole that you would use if the cabinet box bottom wasn't in the way. Both these and the Tandem's could be mounted using a hole 16mm above instead of 12. A simple drill jig that registers to system holes is easier and could have other uses (e.g. drilling holes for rails). If you use both Tandem's and Tandembox's, center indexing is an option. Center indexing isn't pure system, but it has advantages that may outweigh the need to drill extra holes (e.g. maximum storage and a reduced number of box sizes).

Page nine explains the 12mm difference in registration for the page eight Tandembox layout (image): "The lower holes on 358M TANDEMBOX runners are not accessable. Mounting holes must be manually drilled only for the bottom drawer at 58.5mm". Here you have to drill mounting holes 12mm above the system hole that you would use if the cabinet box bottom wasn't in the way. Both these and the Tandem's could be mounted using a hole 16mm above instead of 12. A simple drill jig that registers to system holes is easier and could have other uses (e.g. drilling holes for rails). If you use both Tandem's and Tandembox's, center indexing is an option. Center indexing isn't pure system, but it has advantages that may outweigh the need to drill extra holes (e.g. maximum storage and a reduced number of box sizes).

[ link | top ]

Process 32

There have been at least two versions of Blum's Process 32. The '93 Process 32 was Metabox centric and used incremental panel heights and depths. Panel heights were a multiple of 32 with 64mm top/bottom start holes. System rows were 37 from the front, some multiple of 32mm apart and 83mm from the back. Faces were flush to the top and bottom of the panels. Face to box registration was inconsistent because bottom and full height faces were a multiple of 32mm tall and all other faces were a multiple of 32mm - gap. Using all 32m - g faces is the only way this could be a modular system.

There have been at least two versions of Blum's Process 32. The '93 Process 32 was Metabox centric and used incremental panel heights and depths. Panel heights were a multiple of 32 with 64mm top/bottom start holes. System rows were 37 from the front, some multiple of 32mm apart and 83mm from the back. Faces were flush to the top and bottom of the panels. Face to box registration was inconsistent because bottom and full height faces were a multiple of 32mm tall and all other faces were a multiple of 32mm - gap. Using all 32m - g faces is the only way this could be a modular system.Blum's '04 Process 32 (1.8MB pdf) uses unbalanced panels with 56.5mm top / 46.5 bottom start holes and shifted 32mm increment overlay faces which results in 10/0mm top/bottom reveals (image). Individual and side joined boxes are modular, top joined boxes are not (10mm gap between stacked box faces).

While system rows are a multiple of 32mm apart, box depths are not in 32mm increments. Here, and elsewhere, Blum has opted for American dimensions, e.g. 12 and 24" deep boxes. Only their bottom mount drawer layouts register the drawer faces to boxes consistently, the rest of their layouts shift the bottom drawer slide up 12mm. While Meta and Tandem box drawer sides are in increments of 32mm tall, wood drawers are sized in 2" increments.

32mm system rows and doors (most drawer layouts are not)

See also:

Full Overlay: Other Panel Designs

Drawers: Minus 12

Process 32 VS Plus 32

When using a modular 32mm system, all drawers register to all drawer faces consistently. Distances on alignment fixtures or for drilling adjusters/mounting holes are the same for all drawers. Measurement can be off the top or bottom of the box and face. With full overlay cabinets that consistency comes with a cost, it wastes a lot of space. Plus 32 trades some consistency for better usable space. With Plus 32 measurements can only be off the top of the box and face. Plus 32 moves all waste to the bottom of the box.

When using a modular 32mm system, all drawers register to all drawer faces consistently. Distances on alignment fixtures or for drilling adjusters/mounting holes are the same for all drawers. Measurement can be off the top or bottom of the box and face. With full overlay cabinets that consistency comes with a cost, it wastes a lot of space. Plus 32 trades some consistency for better usable space. With Plus 32 measurements can only be off the top of the box and face. Plus 32 moves all waste to the bottom of the box.In this undermount example, the tradeoff with Process 32 is 20mm less unusable space at the bottom of the cabinet VS inconsistent drawer face registration. Using 32mm increment drawer boxes with Process 32 won't help because the bottom drawer slides are mounted 12mm higher than the rest. Use whatever top reveal you want, the drawings have 49.5mm top starts (3mm reveals, stackable boxes) instead of Process 32's 56.5mm (10mm). The important specifications are the same as the ones in the manual. There's a second drawing showing how to get a 0 bottom reveal with a 48mm start (e.g. for LR32 jig w/ 16mm stops). The only difference is that the faces are shifted down by 1.5mm (different drawer box to face reveals).

See also: Minus 12 and the 3rd 3example in the Full Overlay Undermount topic (maximum space utilization for undermounts that have two rows of mounting holes).

[ link | top ]

Manual

In the '04 manual, box dimensions for kitchen cabinets are on page one. They are your typical American 30-1/2" box (wall and base) plus 4" toe and 1-1/2" counter (36" total). Cabinet depths are also sized to American standards, e.g. 24 and 12" deep. Those American dimensions have a cost, especially if you drill system rows with anything less than a double row boring machine. The difference between using the 32mm increments and American dimensions is 17mm, or approximately 5/8".

In the '04 manual, box dimensions for kitchen cabinets are on page one. They are your typical American 30-1/2" box (wall and base) plus 4" toe and 1-1/2" counter (36" total). Cabinet depths are also sized to American standards, e.g. 24 and 12" deep. Those American dimensions have a cost, especially if you drill system rows with anything less than a double row boring machine. The difference between using the 32mm increments and American dimensions is 17mm, or approximately 5/8". While Blum is heavy on American stantards, I should note that Blum is not alone when it comes to non incremental box depths. This should be discussed in more detail, but the key factor is making the best use of 4x8' sheets. Using applied (instead of dadoed) backs can help when using 32mm increments.

Rail spacing is covered on page two. For some strange reason, only the rails at 606.5mm are centered between system holes. The other rails vary from 1-3mm off center. The 32mm way to handle cross rails is to center them between (or on, whichever is appropriate) system holes, i.e. n x 32mm apart. Because all slides mount to system holes (are the same distance from centered rails), there is no reason not to center the rails. The "Cross rail positions" dimensions are also rather pointless, center to center dimensions is all that matters - it works with 19mm (~3/4") or 16mm (~5/8") stock.

Rail spacing is covered on page two. For some strange reason, only the rails at 606.5mm are centered between system holes. The other rails vary from 1-3mm off center. The 32mm way to handle cross rails is to center them between (or on, whichever is appropriate) system holes, i.e. n x 32mm apart. Because all slides mount to system holes (are the same distance from centered rails), there is no reason not to center the rails. The "Cross rail positions" dimensions are also rather pointless, center to center dimensions is all that matters - it works with 19mm (~3/4") or 16mm (~5/8") stock. Page five has one of their Metabox layouts. The distances from the top of the drawer face to the first mounting hole are missing. That measurement, for all but the bottom left drawer, is 55mm. Using a 320K instead of the 320M and adding another gallery rail would allow you to drill all the faces 55mm from the top. The same is true for system hole registered faces (Blum uses shifted registration) using a Plus 32 layout. Here both drawers can be 320M's and and the distance from the top of the face is 71mm for all the drawers. Note: 71-55=16mm, the same distance as the system row holes are different (start holes and system VS shifted face registration). While indexing drawer faces from the bottom is common, indexing from the top can provide more options (its the only way Metabox indexing can be consistent). You do have to use the system, Blum's 2" increment wood drawer boxes won't work.

Page five has one of their Metabox layouts. The distances from the top of the drawer face to the first mounting hole are missing. That measurement, for all but the bottom left drawer, is 55mm. Using a 320K instead of the 320M and adding another gallery rail would allow you to drill all the faces 55mm from the top. The same is true for system hole registered faces (Blum uses shifted registration) using a Plus 32 layout. Here both drawers can be 320M's and and the distance from the top of the face is 71mm for all the drawers. Note: 71-55=16mm, the same distance as the system row holes are different (start holes and system VS shifted face registration). While indexing drawer faces from the bottom is common, indexing from the top can provide more options (its the only way Metabox indexing can be consistent). You do have to use the system, Blum's 2" increment wood drawer boxes won't work. Page six is is the first example of Blum's 2" increment drawers and the first example of inconsistent drawer registration. Here the distance from the top of the drawer face to the drawer box cannot be the same because the drawer boxes (unlike the Metabox slides/sides) are not in 32mm increments. The distance from the bottom of the face to the box is also not consistent because they mount the bottom drawer differently than the rest (bottom mount hole VS top). See also: Process 32 VS Plus 32

Page six is is the first example of Blum's 2" increment drawers and the first example of inconsistent drawer registration. Here the distance from the top of the drawer face to the drawer box cannot be the same because the drawer boxes (unlike the Metabox slides/sides) are not in 32mm increments. The distance from the bottom of the face to the box is also not consistent because they mount the bottom drawer differently than the rest (bottom mount hole VS top). See also: Process 32 VS Plus 32 Page nine explains the 12mm difference in registration for the page eight Tandembox layout (image): "The lower holes on 358M TANDEMBOX runners are not accessable. Mounting holes must be manually drilled only for the bottom drawer at 58.5mm". Here you have to drill mounting holes 12mm above the system hole that you would use if the cabinet box bottom wasn't in the way. Both these and the Tandem's could be mounted using a hole 16mm above instead of 12. A simple drill jig that registers to system holes is easier and could have other uses (e.g. drilling holes for rails). If you use both Tandem's and Tandembox's, center indexing is an option. Center indexing isn't pure system, but it has advantages that may outweigh the need to drill extra holes (e.g. maximum storage and a reduced number of box sizes).

Page nine explains the 12mm difference in registration for the page eight Tandembox layout (image): "The lower holes on 358M TANDEMBOX runners are not accessable. Mounting holes must be manually drilled only for the bottom drawer at 58.5mm". Here you have to drill mounting holes 12mm above the system hole that you would use if the cabinet box bottom wasn't in the way. Both these and the Tandem's could be mounted using a hole 16mm above instead of 12. A simple drill jig that registers to system holes is easier and could have other uses (e.g. drilling holes for rails). If you use both Tandem's and Tandembox's, center indexing is an option. Center indexing isn't pure system, but it has advantages that may outweigh the need to drill extra holes (e.g. maximum storage and a reduced number of box sizes).

[ link | top ]